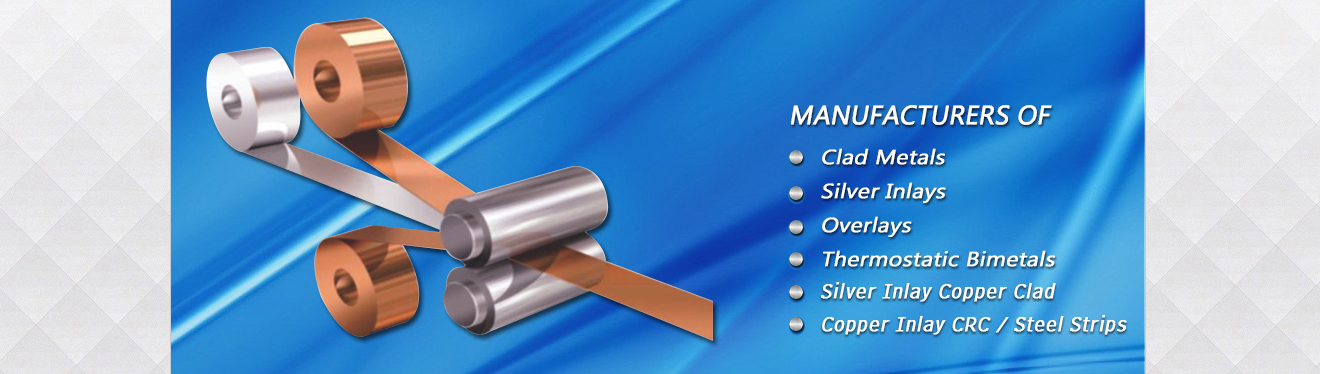

Our Products

Clad Metals

Clad Metal are made by joining two or more metal together through Cold Cladding process. By combining metal, it is possible to create a material that capitalizes on the superior properties that do not exist in a single metal. These properties that do not exist in a single metal. These properties include strength, corrosion resistance, thermal and electric conductivity, weight, surface finish, cost even material availability.

Ultimately, manufactures gain infinite flexibility, as they can choose the exact blend of properties to suit both the manufacturing stage and end application requirements

As a result, Clad Metals offer designers, engineers and manufactures the freedom to create new solutions with targeted properties for even the most unique design challenges. This makes Clad Products an ideal material of choice for Electrical & Switchgear Industry, Petrochemical, Oil and Gas, Construction, Telecommunications, Domestic Appliances, Electronics, Medical, Aerospace and defence industries.

Increased strength compared to pure Aluminum. However, among the most valuable properties of Clad Aluminum, are its superior heat transfer performance and corrosion resistance. This lends itself to many applications, including brazed heat exchangers for the Automotive and Aerospace industries.

Sourcing the right material for a wide range of products is our specialty. So if you would like help in finding the right product for you, get in touch with our sales team today.

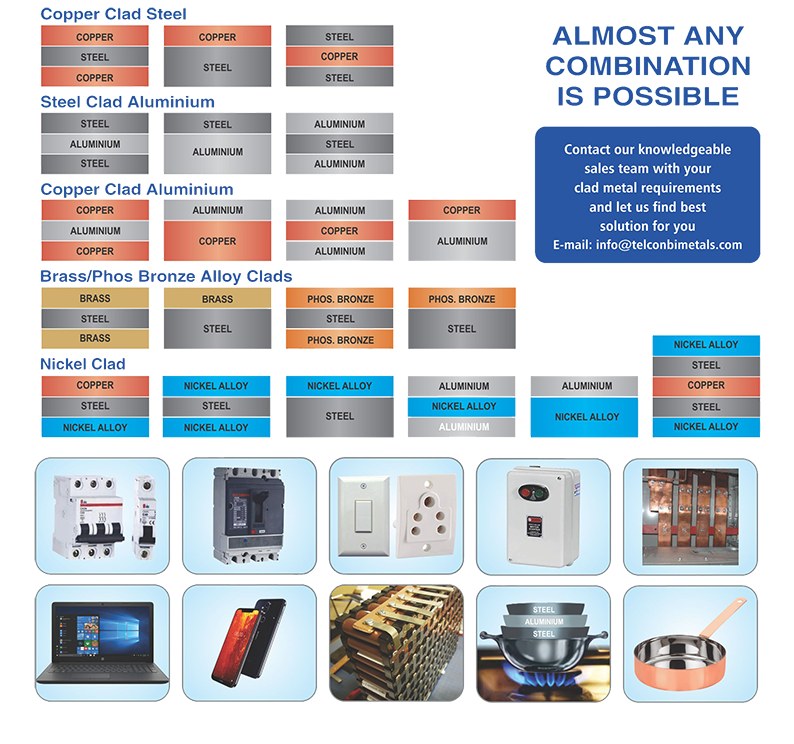

Polpular Configurations

CLAD METAL SOLUTION FOR ANY INDUSTRY:

We offer Custom Clad Metal Applications of full Clads, Inlays, and Toplays to Stampers and OEM's in the switch gears industry, Utensils & Appliances, automotive, computer/laptops, electronics, medical, military, batteries mobile & telecommunications industries and aerospace. Clad Metal Products can be fabricated to accommodate widths between 5mm to 200mm and thickness between 0.5mm to 3.50mm. Virtually any metal combination can be achieved with two to five layers.